As part of its latest Safety Flashes, IMCA analyzes an case of failure of EGS valve stem on dive helmet.

The case:

A member reported an incident in which the emergency gas system (EGS) valve handle on a commercial diving helmet broke off. At the time of the failure the dive helmet was undergoing pre-dive inspection on deck.

What went wrong:

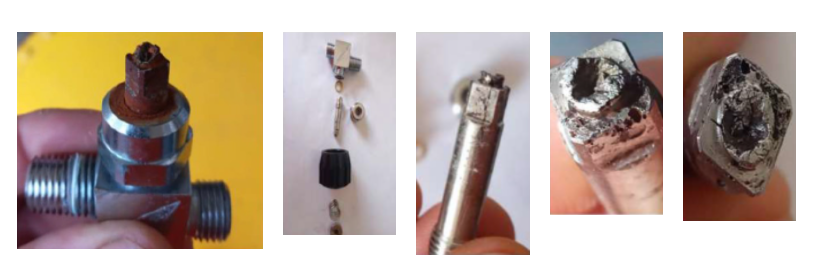

A dive technician stripped the valve and discovered the break to be located at the valve stem – where the threaded portion meets the square section. Both parts of the valve stem, adjacent to the break, were noted to be pitted and a fine hairline crack was noted.

The failed component was replaced with a new spare. Following a gas leak and function test, the dive helmet was placed back into service. The failed component was sent ashore for further investigation.

Findings:

The member arranged an independent laboratory review of the material to try and identify the root cause. The finalised laboratory report indicated that failure occurred as a result of pitting and stress corrosion cracking under the action of the chlorides present in salt water.

Lessons learned:

- Following its investigation our member took the following actions:

- The company preventative maintenance system (PMS) was modified to require NDE dye penetrant testing of EGS valve stems for all base and field diving helmets at a minimum of 12 monthly intervals.

- Internal instructions were issued stating that if the post-dive, inspection, or maintenance routines recommended by the manufacturer highlighted any concerns, the relevant valve stem(s) should undergo immediate NDE dye penetrant testing. If any anomalies are then detected, the component should be discarded and replaced.

SOURCE READ THE FULL ARTICLE

https://safety4sea.com/lessons-learned-failure-of-egs-valve-stem-on-dive-helmet/