Highlighted in Marine Technology Reporter’s MTR100 is the work and technology ongoing in the halls of academia. The most recent report released by the UN Intergovernmental Panel on Climate Change emphasized our warming planet, an expected announcement for many in the scientific community. Faced with the confirmation that human activities have caused an increase in global temperatures, research has turned to seeking answers in the planet’s natural systems. How does each part of the global carbon cycle work and how may it be impacted by the changing climate? What other trends can be observed across the marine industry and what innovative technologies can make positive change?

Shedding light on the twilight zone

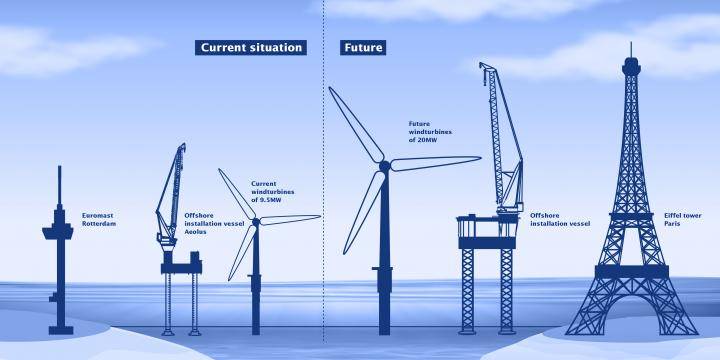

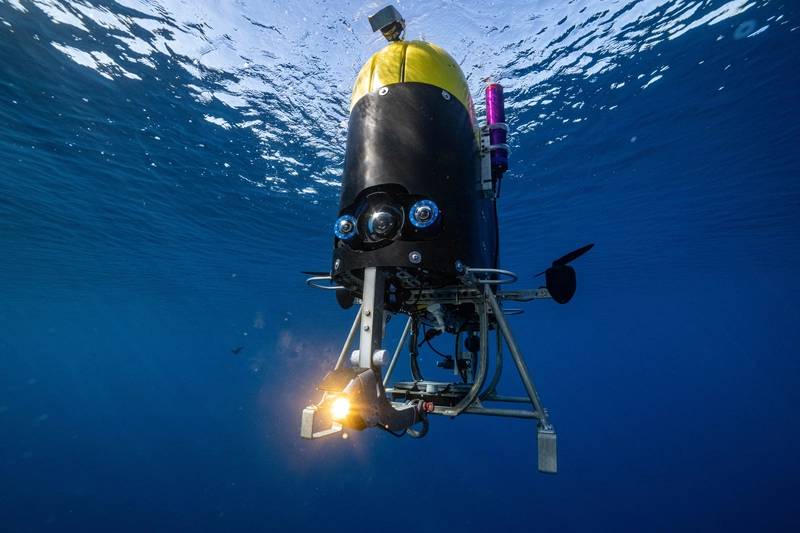

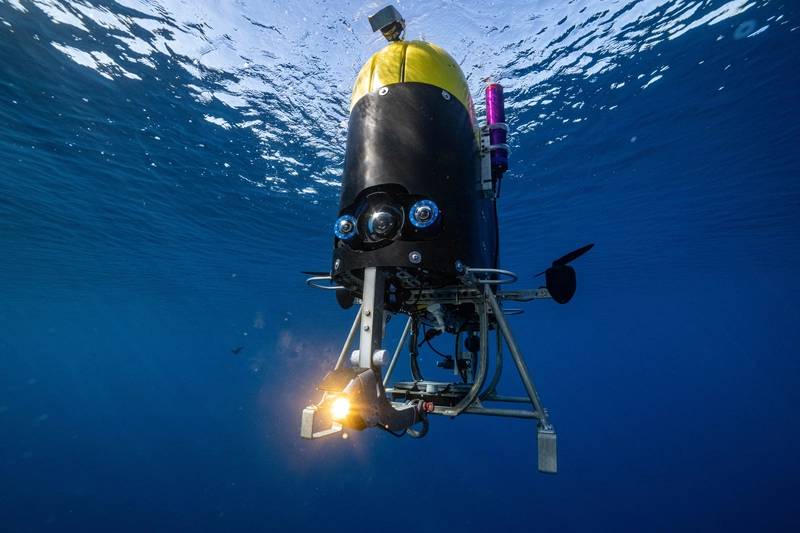

Researchers at Woods Hole Oceanographic Institution (WHOI), in collaboration with Monterey Bay Aquarium Research Institute and Stanford University, have begun addressing this question by seeking to understand how marine creatures transport carbon dioxide to the deep sea, one of the world’s largest carbon sinks. An underwater robot by the name Mesobot is providing scientists with insight into the twilight zone, a vast mid-ocean region.

Mesobot is capable of tracking and recording high-resolution images of zooplankton, gelatinous animals and particles, improving scientists’ ability to observe creatures in their natural habitat with minimal disturbance. The robot, outfitted with oceanographic and acoustic survey sensors, can be piloted remotely through a fiberoptic cable attached to a ship, follow pre-programmed missions, or autonomously track targets up to 1,000 meters deep. “Mesobot was conceived to complement and fill important gaps not served by existing technologies and platforms,” said Yoerger. “Because Mesobot can survey, track and record compelling imagery, we hope to reveal previously unknown behaviors, species interactions, morphological structures and the use of bioluminescence.”

Autonomous tracking, the latter of Mesobot’s three capabilities, could eventually allow scientists to monitor an organism’s behavior during diel vertical migration, a movement pattern during which organisms move to the uppermost layer of the sea at night and return to the twilight zone during the day.

Mesobot, an underwater robot capable of tracking and recording high-resolution images of slow-moving and fragile zooplankton, gelatinous animals, and particles, is providing researchers with deeper insight into the vast mid-ocean region known as the twilight zone. © Evan Kovacs/©Woods Hole Oceanographic Institution

Mesobot, an underwater robot capable of tracking and recording high-resolution images of slow-moving and fragile zooplankton, gelatinous animals, and particles, is providing researchers with deeper insight into the vast mid-ocean region known as the twilight zone. © Evan Kovacs/©Woods Hole Oceanographic Institution

Miniscule, but of sizable importance

Although they exist out of our sight, even microscope marine life plays a crucial role in the health of the oceans—and that of the planet itself—through a biological phenomenon known as marine primary productivity. Through this process, tiny organisms, like phytoplankton, use photosynthesis to consume carbon dioxide and convert it into organic matter and oxygen. The conversion of carbon dioxide into organic matter not only supports oceanic food webs, but contributes significantly to the ocean’s biological carbon pump, a part of the global carbon cycle that has become increasingly more important to track and understand in recent years. Researchers at MBARI, including senior scientist Ken Johnson, have demonstrated how a fleet of robotic floats can improve our understanding of marine primary production on a global scale.

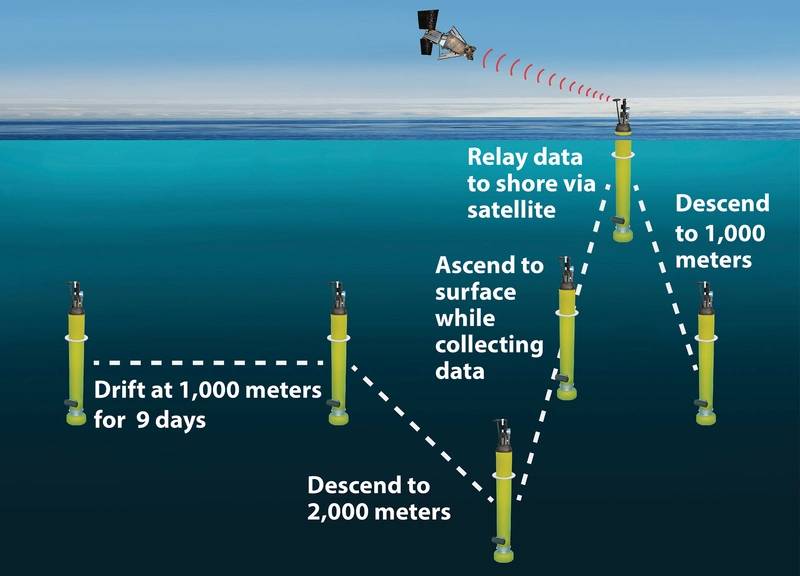

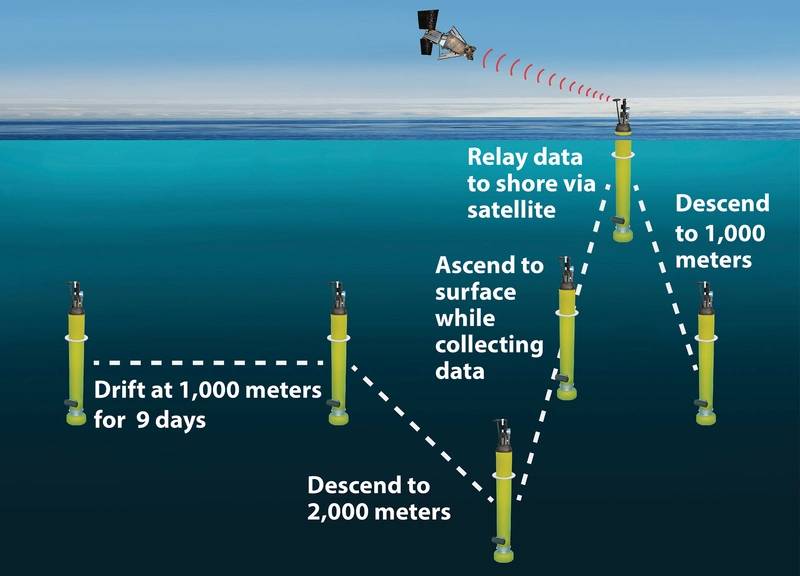

“The technology we use is a big array of biogeochemical-Argo robotic profiling floats that are equipped with chemical and biological sensors. For the productivity work, we used oxygen sensors to detect the increase in oxygen that is created by photosynthesis and the chlorophyll sensors to detect how deep light (needed for photosynthesis) is penetrating,” Johnson explained. “Each float profiles from about 2 km depth to the surface every 10 days, making measurements on the way up. At the surface, each float sends the data home through the Iridium satellite network.” Phytoplankton consume carbon dioxide and release oxygen at a specific ratio, and by measuring oxygen release over time, scientists can better understand the role played by marine life in the carbon cycle. By combining the work of hundreds of floats that reach the surface at various times of the day, Johnson’s team can recreate the daily carbon cycle and calculate a more accurate primary productivity. “This allowed us to get the mean, daily cycle of oxygen over the global ocean and the first, direct measurement of global ocean primary productivity,” said Johnson.

Marine primary productivity changes in response to climatic fluctuations (temperatures, ice, currents, etc.) and monitoring this shift is crucial to understanding climate change. Previously, tracking this response on a global scale has been difficult due to human and technological setbacks. “Primary productivity is the key to ocean ecosystem function and change. Phytoplankton use photosynthesis to create the organic carbon that fuels the whole ocean ecosystem. Lower primary productivity, probably fewer fish. More primary productivity, maybe more fish. But we just don’t have direct observations at the global scale to see what is happening,” Johnson said. This data will allow scientists to better predict how marine primary productivity may change in response to our changing climate—including warmer waters and ocean acidification. “This is just the start; we don’t have enough data to say how primary productivity is changing – we’re just establishing a baseline for the modern ocean.”

Hydrophone-equipped Slocum gliders are listening for the calls of North Atlantic right whales and transmitting the animals’ locations in near-real-time to ships and vessels in the area. Results from the work aim to reduce the number of whale-ship collisions and are assisting with the protection of critical whale habitats. © Nicolas Winkler

Hydrophone-equipped Slocum gliders are listening for the calls of North Atlantic right whales and transmitting the animals’ locations in near-real-time to ships and vessels in the area. Results from the work aim to reduce the number of whale-ship collisions and are assisting with the protection of critical whale habitats. © Nicolas Winkler

Kelp calm and carry on

Marine plants, too, could provide an answer to the ocean’s role as a carbon sink. New Zealand’s National Institute of Water and Atmospheric Research, with the help of drones and underwater ROVs, is conducting research to assess the health of kelp and seaweed forests. Marine plants play an enormous role in marine ecosystems and the warming climate by absorbing carbon emissions and monitoring their health is crucial to understand the impacts of rising temperatures.

On behalf of the Department of Conservation, marine ecologist Dr. Leigh Tait and environmental monitoring technician Hamish Sutton have launched pre-programmed flights over shallow reef in the Taputeranga Marine Reserve. Hanging off the bottom of the drone is a multispectral camera, able to register colors invisible to the human eye. Throughout its flight, a photo is taken every two seconds. Thanks to rubber maps laid out in the water to relate the images to real features on the ground, the photos are stitched together into 2D or 3D models. The images are then run through computer software training to identify the types of seaweed.

In the kelp forests of Antarctica’s Ross Sea, underwater ROVs are playing a role in ecosystem health assessment, too. The BoxFish ROV in question can survey Antarctic marine life more than 100 meters below the surface with its sensors and high-definition cameras, tethered to a surface ship with fiberoptic cables for data transfer. A recent survey uncovered surprisingly deep and dense stands of kelp, furthering questions about their role in the marine carbon cycle. “It really opens up a whole new field of research in how those plants are taking CO2 out of the atmosphere and storing that in the deep cold sea. We really know very little about that,” Dr. Leigh Tait said.

A biogeochemical-Argo (BGC-Argo) float collects data between the surface and 2,000 meters deep over 10 days. © Kim Fulton-Bennett 2020 MBARI

A biogeochemical-Argo (BGC-Argo) float collects data between the surface and 2,000 meters deep over 10 days. © Kim Fulton-Bennett 2020 MBARI

A Whale of a Challenge

Recent research in academia also includes marine organisms that exist very much in our sight—whales. A collaborative initiative between the Ocean Tracking Network (OTN), the Ocean Frontier Institute, and the Marine Environmental Observation Prediction and Response Network is working towards their protection. Using a fleet of OTN gliders operated by the Coastal Environmental Observation Technology and Research group based at Dalhousie University, the project monitors North Atlantic right whales in the gulf of the St. Lawrence River using autonomous underwater gliders.

OTN executive director Fred Whoriskey explained the technology behind the Teledyne Marine Slocum gliders in use. Each is battery-powered and can remain at sea for up to four months. They contain an engine to adjust buoyancy as needed and move at a speed of about one knot, reaching depths of up to 1,000 meters. The glider can carry various instruments, such as thermometers or conductivity meters, and collects data as it moves through the water column, which is stored to an onboard memory system until it reaches the surface and transmits all information via satellite. Slocum gliders, as in Dalhousie’s case, can also be outfitted with a digital acoustic monitor (DMON), a device developed by Woods Hole Oceanographic Institution scientist Mark Baumgartner. The DMON can record the calls of North Atlantic right whales (as well as other large whales) and the transmitted data can help authorities avoid collisions with vessels.

The recent move of the whale species from its traditional seasonal feeding grounds in the Bay of Fundy and the Roseway Basin to the Gulf of St. Lawrence has increased the risk of vessel collisions and fish gear entanglement. “Right whales are critically endangered, and we are at a point where we must do everything possible to avoid human induced mortalities or injuries to the species to help the species recover,” Whoriskey said. “The glider program is part of an effort to inform human activities, notably fishing and shipping, that have been shown to be the major causes of right whale mortalities in recent years.”

MBARI researchers demonstrated that a fleet of robotic floats could provide important insight into ocean primary productivity on a global scale. © Natalie Freeman 2019 SOCCOM

MBARI researchers demonstrated that a fleet of robotic floats could provide important insight into ocean primary productivity on a global scale. © Natalie Freeman 2019 SOCCOM

Pervasive plastics

Beyond the questions posed by the global carbon cycle and recent news of the warming planet, other significant marine crises, such as microplastic pollution, remain at the forefront of research. In some cases, solutions to clean our waters of plastic particles go beyond the traditional macro plastic pollution cleanups and sifting through water. On occasion, scientists look towards nature for the answer.

The star of this show, as demonstrated through research conducted by the Plymouth Marine Lab (PML), are mussels. Mussels are hardy and robust, able to survive in polluted waters, and are filter feeders—they get their food by filtering seawater to get plankton and other nutrients while flushing out unwanted particles from their digestive systems. “Several laboratory-based studies have previously shown that mussels can filter microplastics out of the water, so we wanted to take a closer look at exactly how effectively mussels could do this and how this knowledge could be applied in the real world to help provide a nature-based solution to plastic pollution,” explained Pennie Lindeque, Head of Science for Marine Ecology and Biodiversity.

Initial experiments involved a specially designed flume tank that circulated water to mimic estuary currents. The blue mussels (Mytilus edulis) were given algae and microplastics to feed on, and over the course of two hours, the bivalve mollusks had removed half of the microplastics present. The particles are rejected by the mussels as fecal matter, which sinks and can be collected for removal. With this knowledge, PML scientists used computer models to place hypothetical “ropes” of mussels every 100 meters at the mouth of estuaries to predict how much plastic could potentially be removed, Lindeque explained. “These models indicated that mussels situated near the mouths of rivers and estuaries could filter between 20-25% of small, waterborne microplastics.” Further tests include a series of trials in a Plymouth marina using clusters of mussels in large baskets; the feces (and microplastics) are collected by net-like receptables below the baskets.

While the factors involved are complex—physical parameters include depth, currents, tides and temperatures—the findings show that a mussel-based cleaning system could provide positive effects in estuarine areas, especially in places were microplastics may accumulate, like harbors or near wastewater treatment plants. “Ultimately, we need to be thinking about making plastics part of a circular economy, where end-of-life plastic is reused, recycled or safely disposed,” said Lindeque. “In the meantime, we hope that by using natural ecosystems and processes, like the mussels’ filtering ability, we can help stem the flow of microplastics into our oceans.

With the recent IPCC report still fresh in our minds and limitless questions to tackle on the horizon, marine research faces boundless expectations, yet continues to make significant advances. Issues like increasing levels of carbon dioxide, endangered species and plastic pollution are just three of many that face marine ecosystems and coastal communities. In this sense, academia plays a unique role in identifying crucial trends and influencing technological development and societal action. Between innovative solutions and the motivation to understand and protect the planet, research will continue to uncover new findings and pave a path towards a cooler future.

Dr Rachel Coppock and Dr Matthew Cole with the experimental equipment. © PML

Dr Rachel Coppock and Dr Matthew Cole with the experimental equipment. © PML

SOURCE READ THE FULL ARTICLE

https://www.marinelink.com/news/academias-climate-change-challenge-far-491021