COVID-19 is accelerating technological advances across just about every industry, from robotic baristas that promote social distancing to AI and remote collaboration tools that help manual laborers get back to work. The pandemic has had a direct impact on the transport realm, with social distancing measures calling traditional modes of travel into question. Demand for ride-hailing services quickly plummeted with the advent of the pandemic, leading Uber to double down on food delivery and micromobility, while drone deliveries soared. And while autonomous vehicle companies have faced significant obstacles to real-world testing, early signs suggest the crisis could hasten the adoption of driverless vehicles.

But automobiles, trucks, and drones are only part of the autonomous transport picture. Ships and other seafaring vessels play a huge role in the global economy. As lockdowns ease and the world adapts to a new paradigm, maritime automation could gain significant traction.

Not shipshape

According to the International Chamber of Shipping (ICS), maritime vessels constitute around 90% of all international trade — making them, as ICS puts it, the “lifeblood” of the global economy. But boats are also floating petri dishes.

In The Geography of Transport Systems (2020), Dr. Jean-Paul Rodrigue and coauthors drew correlations between transportation and pandemics, with specific reference to the Spanish Flu. They highlighted one of the key reasons 100 million people died and 30% of the world’s population became ill:

One important factor why the Spanish Flu spread so quickly and so extensively was through modern transportation, which at the beginning of the 20th century offered global coverage. The virus was spread around the world by infected crews and passengers of ships and trains, and severe epidemics occurred in shipyards and railway personnel.

In short, transportation plays a pivotal role in the spread of viruses, which is why airlines, trains, subways, taxi services, and boats saw such huge drops in usage following outbreaks of COVID-19.

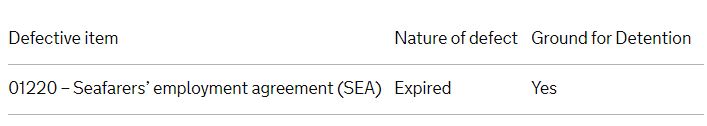

Cargo and passenger ships around the world have been turned away from ports by local authorities, with as many as 300,000 merchant sailors stranded at sea for months, far beyond their contractual agreements. In April, ICS and the International Air Transport Association (IATA) issued a joint call demanding governments “take urgent measures” to facilitate crew change flights.

While the implementation of autonomous technology is not yet widespread enough to turn the tide on COVID-19, many are already looking to the future. And companies that have been working to bring automation to the shipping industry are now poised to enter a world wary of pandemics.

Avoidance

Tel Aviv-based Orca AI is developing a collision avoidance system that is currently being piloted by a number of shipping companies globally, CEO and cofounder Yarden Gross told VentureBeat. The company applies its algorithms to data extracted from multiple sensors installed on a vessel, including thermal and low-light cameras, to detect and measure the distance to other vessels and objects in the water. “We then provide [a] risk assessment of any detected object and vessel to enable the crew to be more aware of potentially dangerous situations,” Gross said.

Above: Orca AI

While radar and other systems have long been used at sea, they may require constant monitoring and can’t always alert crews to a hazard or issue actionable recommendations. This problem becomes particularly pronounced when multiple vessels or obstacles are in close proximity. Throw into the mix crowded or narrow waterways and low-light conditions and it’s easy to see why at least three-quarters of maritime accidents are caused by human error, at least according to liability claims data.

Orca AI is banking on technology to turn the tide. “The shipping industry is one of the most conservative industries in the world, and the pandemic is creating an increased demand for digital tools, automation, and connectivity, in order to reduce the number of people involved in the whole process,” Gross said.

Above: Orca AI’s collision avoidance system at work

The transition to fully autonomous ships will take time, particularly for large vessels that travel thousands of miles between continents. This shift could mirror the evolution of autonomous cars and trucks, beginning with semi-autonomous technologies, such as collision avoidance systems, and initially focusing on narrow use cases on predefined routes.

The vast majority of maritime accidents happen in ports, straits, and canals, which is where Orca AI is currently focused. “This is where the existing equipment is lacking in efficiency and accuracy,” Gross said. “Today, systems don’t take full control over vessels, but gradually there will be more autonomous capabilities. It will be similar to aviation, where there is still a pilot, but most of the time the computer is controlling the plane and the pilot is supervising and doing other tasks. In autonomous shipping, there will still be a crew, but there will be more and more tasks done autonomously.”

“Marine pilotage” is a term for specially trained mariners who board ships near the port to guide them through domestic waterways, often providing local knowledge of water-based thoroughfares that the captain doesn’t have. This task is sometimes carried out “remotely,” particularly during adverse weather conditions, with pilots on smaller boats guiding a big ship to safety or offering instructions from a control center. However, the COVID-19 crisis could be expediting such efforts, as a number of ports have been forced to embrace remote pilotage for ships or crew arriving from high-risk countries.

In late March, the Italian cruise ship Costa Diadema reported 65 cases of COVID-19 on board. To pass through the Suez Canal without a pilot physically boarding the ship, a team on tug boats maneuvered it using radar and information from monitoring stations along the route. Similarly, a U.K. fishing port in April introduced remote pilotage for vessels entering its harbor.

While remote pilotage might not entirely replace traditional methods, technology can make the work more efficient and safe. Orca AI promises to help pilots do their work remotely by “streaming the data from the cameras and other sensors back to shore in real time,” Gross said. “Orca is in discussion with a few ports regarding this.”

Going local

Norwegian chemical company Yara International and technology group Kongsberg have been working on the Yara Birkeland Autonomous Ship Project since 2017, with plans to put an electric, autonomous container ship into service. This effort would span three ports and 12 nautical miles in southern Norway.

Above: Yara Birkeland’s proposed route in southern Norway

Above: Yara Birkeland

The ship, which sports various sensors, including radar, lidar, and infrared cameras, has an automatic mooring system — berthing and unberthing will be done without any human intervention. Along the route, operation centers will be equipped to handle emergency situations remotely and support the onboard AI’s decision-making.

Above: Kongsberg’s operational control center for the Yara Birkeland

The Yara Birkeland will have a crew initially, and the transition to full autonomy will be done in stages, thanks in part to the development of a detachable bridge (command center).

“Even before the vessel starts its operation, there will be a level of automated capabilities for maneuvering, positioning, moorings, and supporting the crew,” An-Magritt Tinlund Ryste, product director for next-generation shipping at Kongsberg, told VentureBeat. “We foresee that we will be required to implement new autonomous functionality gradually to verify the performance in real-life operational scenarios before we arrive at the final stages where the vessel, the connectivity solution, and the remote operation center are sufficiently tested to allow for unmanned operation.”

While the Yara Birkeland was scheduled to transition to full automation by 2022, the COVID-19 crisis has forced developers to “pause” work on the project. Such setbacks are not ideal, but Ryste suggested the pandemic could accelerate the broader autonomous ship movement, as “ship owners and operators have an increased incentive to invest in new technology for the future, with a focus on support and surveillance from land.”

The Yara Birkeland represents part of Kongsberg’s wider effort to bring more autonomy to seafaring vessels. The company has already developed and demonstrated autocrossing and autodocking technology, and the first “adaptive transit” passenger ferry service traveled from dock to dock earlier this year. This was done through a collaboration between the Norwegian Maritime Authority (NMA), shipping company Bastø Fosen, and Kongsberg. The launch kick-started a six-month trial, during which Kongsberg’s system controlled the ferry’s journey from start to finish, with a captain overseeing the trip from inside the bridge. The next step is to install an anti-collision system, and tests are scheduled for later this year.

Kongsberg partnered in 2018 with maritime industry group Wilhelmsen to launch a joint venture called Massterly, designing land-based operation centers to monitor and control autonomous ships in Norway and further afield. This echoes what we’re seeing in the broader autonomous vehicle realm. Sweden’s Einride recently showcased remote driving stations where teleoperators — many of them former truck drivers — can take control of Einride’s autonomous trucks when required, with an operator able to control multiple vehicles from a single station.

Above: Einride operators will be able to control multiple autonomous trucks from a single remote station

Einride demonstrates that while some jobs will be lost to AI and automation, new ones will be created. For autonomous shipping, this could mean new roles for staff overseeing ships remotely. This shift will also expand the talent pool to include people in new locations.

“Remote services are here to stay,” Ryste continued. “We see it working well for people working from home, and with more sensors and connected vessels, the need for having a service engineer on board also decreases. This gives you access to an expert in a time zone convenient for the vessel crew.”

The pandemic will likely accelerate efforts to incorporate autonomous technology in shipping. “I think that what has happened during the COVID-19 crisis will strengthen the argument for the push toward autonomous ships,” Kongsberg research and innovation manager Jason McFarlane told VentureBeat. “In particular, in relation to the restriction of people’s movement and the challenges with crew changes. Autonomous shipping, especially for unmanned vessels, should allow freight and cargo to be transported internationally and across borders without being affected by restrictions on people’s movement.”

We’ve already seen similar activity in other industries — from the passage of laws to updated corporate work-from-home policies and the adoption of new technologies. In the shipping industry, as with others, such changes could open the door to a more permanent shift.

“The focus has changed, and we see that even if restrictions are lifted temporarily, opening up for testing new solutions might just become a permanent solution as we adapt to new methods or technology,” Ryste added.

Research in motion

Next year, Promare — a U.S.-based marine research and exploration organization — is scheduled to send a crewless ship across the Atlantic Ocean on the route the original Mayflower traveled 400 years ago.

Above: Mayflower Autonomous Ship route map

The Mayflower Autonomous Ship (MAS) is chiefly propelled by solar power, with a diesel generator on board as backup. IBM will power an onboard “AI Captain,” with the ship leveraging edge computing for its AI and navigational smarts. All the data processing must be available on the ship because a vessel in the middle of the ocean can’t rely on satellites or cloud connectivity.

The team behind the new Mayflower has trained the ship’s AI models using millions of maritime images collected from cameras in the Plymouth Sound, among other open source data sets. The Mayflower’s AI Captain is built to detect and identify ships and buoys — as well as other hazards — and to make decisions about what to do next. An onboard automatic identification system (AIS) can also access specific information about any vessels ahead, including their class, weight, speed, and cargo type, while the AI Captain can accept and interpret radio broadcast warnings from a cargo ship.

Above: The Mayflower Autonomous Ship’s AI Captain in operation

This ship will carry research pods to gather data about ocean health, while simultaneously showcasing how an autonomous research vessel can manage on its own for two weeks at sea. It also sets the stage for further use cases, from defense and commercial shipping to marine insurance.

“Right now, we are focused on increasing the reliability of our autonomous systems and developing an ecosystem of partners — from IBM to equipment manufacturers to telecoms providers to insurance providers — to figure out how to commercially deploy the systems we have on [the] Mayflower,” Mayflower Autonomous Ship director Brett Phaneuf said. “What we are doing here is very much a research project for something much bigger than this one ship.”

AI and autonomy could certainly provide utility beyond cargo vessels. Research ships may spend weeks or months at sea collecting data about the ocean, and removing crews would facilitate longer missions by taking food storage and personal well-being out of the equation. In terms of the COVID-19 crisis, more automation could mean fewer people on board, which should help with social distancing efforts.

“We are already seeing the early examples of autonomous ferries, cargo ships, and research vessels like the Mayflower Autonomous Ship,” Phaneuf continued. “But perhaps the greater, more immediate need for autonomy is on manned vessels. This may sound counterintuitive, but there is an important role for autonomous systems on the manned ships of today, acting as a cocaptain, maintaining situational awareness, [and] providing recommendations and decision support to the human crew.”

We’re talking about “augmented intelligence,” as Phaneuf puts it, with machines helping people accomplish core tasks and reduce risks.

“A trusted autonomous system can reduce the stress on the bridge by consistently monitoring the overall navigational situation of the vessel,” Phaneuf added. “This will allow humans to get their heads up and out of the computer screens and instead looking out the window and doing what humans do best — making complex decisions swiftly and accurately.”

It might not make sense for certain types of vessels to become completely autonomous, whether for logistical, regulatory, or financial reasons. “This is not likely to be a zero-sum game, but more of a hybrid approach,” Phaneuf continued. “For example, it may not make sense to replace the whole crew of a container ship with a fully autonomous system because the cost of the crew actually represents very little in the overall value of the ship and its cargo. As such, there may not be an economic driver for this level of change. However, there are other factors to take into consideration — such as the well-being of the crew and equipping people with the skills they need for the shipping industry jobs of the future.”

The future of autonomous shipping

Many newer ships are already highly automated, at least in terms of being able to passively gather performance metrics for remote analysis, and technology can also enable diagnostics and repairs from afar. But the pandemic has highlighted the role automation can play.

Global trade today relies on ships and crews traversing vast oceans, and fully autonomous cargo vessels that can cover these distances are likely still a long way off, if they ever arrive. Barriers include technological and regulatory constraints, not to mention practical obstacles, such as the need to carry out maintenance on longer voyages. Domestic journeys are a natural starting point for autonomous ships because they don’t require international cooperation, and a vessel that remains relatively close to shore — such as the Yara Birkeland on its proposed route in southern Norway — can adhere to safety standards with on-shore personnel able to physically (or remotely) intervene in an emergency.

“From a regulatory perspective, the challenge (with longer, international automated routes) lies within the fact that the IMO (International Maritime Organization) does not have a common and internationally acknowledged way of granting approval [for] such vessels as the Yara Birkeland,” Ryste said. “This means there is a likelihood of encountering varying rules and regulations between flag states and port authorities. This is manageable for point-to-point operation but will be a too-demanding administrative task when more parties are involved — at least, at the moment.”

As COVID-19 shifts global structures and accelerates innovation, we’re already seeing how autonomous tools could help ships continue operating through future pandemics. And while some jobs will likely be lost as automation takes hold, technology is unlikely to replace humans across the board.

“For decades, autonomous systems have been used to assist humans in dangerous work, such as clearing up after accidents or dealing with highly dangerous substances or infectious diseases,” Phaneuf noted. As autonomous systems improve, their role “will likely increase, but [it] will need to be part of a larger, interconnected network of manned, unmanned, automated, and autonomous systems on water, in air, and on land.”

Source: venturebeat