EcoClipper, a Dutch start-up company working to develop a fleet of zero-emission sail-powered cargo ships, is using 21st-century technology to perfect wind propulsion to provide sustainable transportation for cargo, passengers, and trainees around the world. UK-based engineering consultants Cape Horn Engineering is partnering with EcoClipper to apply its expertise in computational fluid dynamics to advance the design of the modern sailing ships.

Founded in 2018, EcoClipper plans to develop a fleet of ships that will sail on four shipping lines with fixed schedules, thereby creating a new shipping logistics system for sail cargo vessels. The concept calls for three regular routes to be established, starting with the Atlantic sailing from the English Channel to the United States and the Caribbean. The Pacific route would sail from California to China and Japan, and the most ambitious is a traditional route sailing around the world using the westerly wind patterns.

The inspiration and starting point for the design of the modern vessels was based on the design of the Dutch sailing clipper Noach, launched in 1857 and reported to have been the fastest Dutch sailing vessel ever built. The EcoClipper 500 will be built in steel with modern construction techniques. According to the company, each vessel will be able to carry 500 tons of cargo along with a crew of 12, 36 trainees, and up to 12 passengers.

“The historic records of Fop Smit’s Noach are extensive,” says Jorne Langelaan, sail cargo expert and founder and CEO of EcoClipper, nothing that the design of the historic ship was built around cargo carrying capabilities and passenger comfort. He, however, wants to test different hull shapes to ensure the best performance of the modern ship. “With Cape Horn Engineering’s expertise, we are able to fine-tune the ship to make sure it can sail as fast as possible, whilst retaining these necessities.”

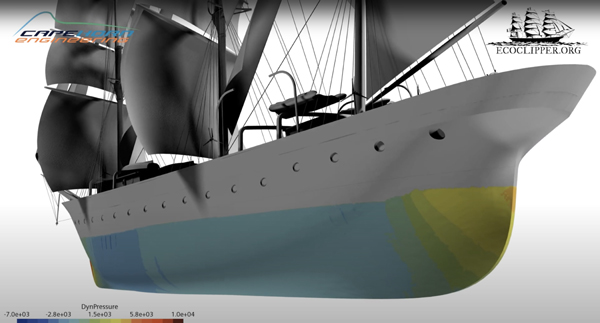

CFD simulation for the EcoClipper design (Cape Horn Engineering)

Cape Horn Engineering’s expertise focuses on optimizing the design of many composite vessels using its experience in hydrodynamics and specialization in computational fluid dynamics (CFD). The engineers use high-fidelity RANS-based simulation techniques where accurate forces and moments are obtained for the given shape candidates and operating conditions.

For the EcoShip project, Cape Horn explains that an ambitious R&D program was agreed and extensive CFD simulations for four different candidate hulls were performed and compared at different sailing conditions to aid the design process. Dr. Rodrigo Azcueta, managing director of Cape Horn Engineering explained that CFD technology is a crucial support for naval architects to optimize designs for critical elements such as weight saving, performance predictions, reducing emissions, and ship optimization.

One of the main challenges the engineers faced said Azcueta was to compare fairly dissimilar hull shape candidates without the aid of a Velocity Prediction Program, where all hydro and aero forces are balanced. With the complex sail plan for the EcoClipper 500, which consists of three square-rigged masts, a maximum of 29 sails (including stunsails), and the maximum sail area being around 1580m2, the generation of a full aerodynamic model was out of the scope of the project. Therefore, sail coefficients for similar sailing vessels found in literature had to be used, to give a relationship between the driving force, side force, and heeling moment, to enable accurate calculations to be made for the hydrodynamic performance of the hull candidates.

Another detailed investigation was aimed at finding the best possible position to install the hydro-generators that will provide the electricity requirements of the vessel. Velocity maps around the hull were analyzed to find the locations with the most homogeneous and higher speeds for the best performance of the turbines.

Using these advanced engineering capabilities, EcoClipper reports that it is further advancing the sustainability of the project. The company’s previous research showed that the most sustainable way to transport cargo and passengers is using a traditional design of vessels, the Clipper ship, with square-rig sails. EcoClipper previously reported that it is examining the financial market to build its first ship.

SOURCE READ THE FULL ARTICLE

https://www.maritime-executive.com/article/cape-horn-engineering-refines-designs-for-sail-powered-cargo-ships